Tesla's safety system relies on advanced sensors, cameras, and software like ADAS, AEB, LKA, and Autopilot for passenger protection. Validation involves extensive testing of these components in simulated real-world scenarios by auto body shops, focusing on functionality, accuracy, and responsiveness. Rigorous tests include controlled collisions and dent removal, ensuring safety system effectiveness and vehicle sustainability. Real-world driving simulations assess Autopilot and collision avoidance responses, reassuring Tesla owners of optimal vehicle condition after every drive.

Performing thorough Tesla safety system validation is crucial for ensuring the electric vehicle’s advanced driver-assistance systems (ADAS) operate optimally. This process involves a multi-faceted approach, starting with understanding key components like cameras, radars, and ultrasonics. Next, conduct comprehensive sensor testing to verify data accuracy. Simulate real-world driving scenarios to challenge the system, ensuring it responds appropriately in various conditions. By adhering to these procedures, you’ll facilitate effective Tesla safety system validation.

- Understand Tesla Safety System Components

- Conduct Comprehensive Sensor Testing

- Simulate Real-World Driving Scenarios

Understand Tesla Safety System Components

The Tesla safety system is a complex network of sensors, cameras, and software designed to protect both passengers and other road users. To effectively perform Tesla safety system validation procedures, it’s crucial to have a solid understanding of its various components. This includes recognizing the role of advanced driver-assistance systems (ADAS), such as automatic emergency braking (AEB) and lane keeping assist (LKA). These technologies rely on radar, lidar, and computer vision sensors to detect obstacles, track other vehicles, and make split-second decisions to mitigate potential crashes.

Additionally, Tesla’s safety system incorporates features like Autopilot, which enables semi-autonomous driving capabilities, further emphasizing the need for meticulous validation. During validation procedures, auto body shops or professionals specializing in vehicle dent repair must inspect and test these components to ensure their optimal performance. By simulating real-world scenarios and utilizing specialized equipment, they can verify the safety system’s effectiveness in preventing accidents and responding appropriately to critical situations, thereby enhancing overall vehicle safety and peace of mind for Tesla owners.

Conduct Comprehensive Sensor Testing

To ensure optimal performance of the Tesla safety system validation procedures, comprehensive sensor testing is paramount. This involves meticulously examining each sensor’s functionality, accuracy, and responsiveness—from camera resolution to radar range and LiDAR precision. By simulating various scenarios, including sudden stops, lane departures, and obstacles, engineers can validate the system’s ability to detect and react accurately in real-world conditions.

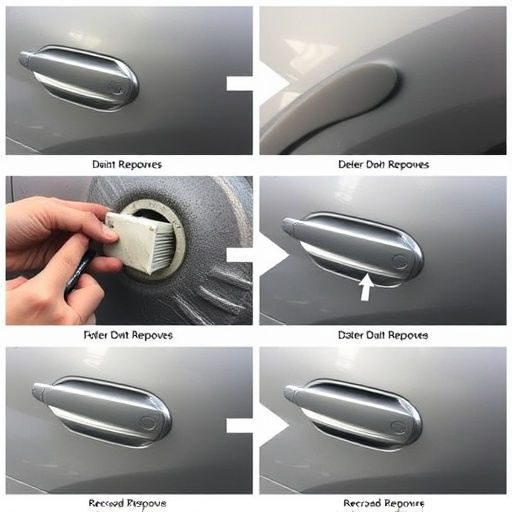

Such testing goes beyond mere simulation, encompassing real-world tests, such as controlled fender bender exercises, to gauge the safety system’s effectiveness in mitigating damage and ensuring passenger safety. This rigorous process not only validates the technological capabilities of Tesla’s safety systems but also paves the way for advancements in automotive collision repair and paintless dent repair techniques, enhancing overall vehicle safety and sustainability.

Simulate Real-World Driving Scenarios

To effectively validate Tesla’s safety system, it’s crucial to simulate real-world driving scenarios. This involves recreating various situations that drivers might encounter on a daily basis, such as sudden lane changes, emergency braking, and obstacles on the road. By using advanced simulation tools and test tracks, engineers can assess how the vehicle’s Autopilot and collision avoidance systems respond under different conditions. These tests are vital for ensuring the safety and reliability of Tesla vehicles in diverse environments.

Simulating real-world driving scenarios also allows for a comprehensive evaluation of the system’s performance in terms of car dent removal—both during normal operations and in extreme cases. Just as vehicle restoration is an important part of maintaining any car, testing the safety system under various conditions helps identify potential issues and ensures that the vehicle can return to optimal condition after every drive, providing peace of mind for Tesla owners.

Performing thorough Tesla safety system validation is paramount for ensuring autonomous driving capabilities meet the highest standards. By understanding key components, conducting rigorous sensor testing, and simulating real-world scenarios, professionals can validate the system’s effectiveness and reliability. These steps are essential in the ongoing development and refinement of Tesla’s safety technology, ultimately contributing to safer and more efficient electric vehicle experiences.